It is a long way from the beginning in the barn on Rii’s main farm to the modern factory premises in Kongsvinger where Stantek AS has been located for almost fifty years. The history of the punching company is a story of ingenuity, courage, professional skill, adaptability, sobriety and business acumen. A success story, in short.

Many enterprising men from the great valleys came to the capital in the years after the Second World War. One of them was Gunnar Aalrust from Hemsedal. He was an imaginative young man, who was always on the lookout for new and better opportunities. In the first couple of years, he was mostly involved in the food trade in various forms, but then he got a tip about a newly started punching workshop that could be interesting. Stanseprodukter AS was started in 1945, and now they were looking for a partner. Gunnar Aalrust bought in with a third.

A company in development

Gunnar Aalrust was an impatient and energetic man, who was constantly looking for new solutions and products. The old barn on venerable Rii’s main farm was buzzing with activity, and after a couple of years of business, Aalrust bought out its old partners.

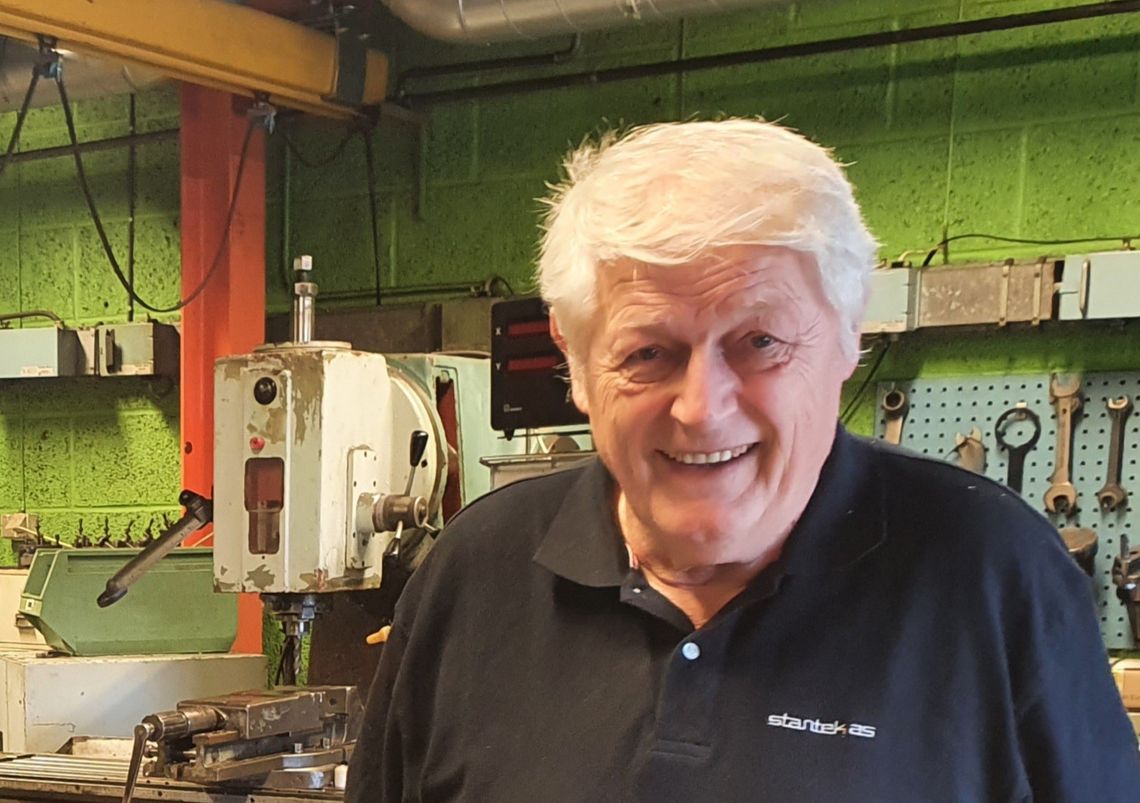

– Father had incredible courage. He often used the expression that one should go on like a blind pig, says his son Bjørn Aalrust, who, together with his older brother Oddvar, took over the business when his father retired at the end of the 70s.

– Father was good at getting hold of good people. Not least, the company has always had a very capable tool department. They produced good things. For example, they made a stapler that was assembled completely without screws.

Moved to Kongsvinger

As the business grew, Stantek AS had to find new premises. First in 1960 to a 1,800 square meter factory at Ammerud in Oslo, and in 1974 to SIVA at Kongsvinger. Here the company built a 3,500 m2 large and modern production facility. In the 1960s, among other things, Stantek AS produced seat belts for cars. According to Bjørn Aalrust, this safety harness, which incidentally received the comprehensive name Trygg, is confusingly similar to what you find on airplane seats today. In addition to staplers and safety belts, Stantek AS has also had success in periods with items such as window fittings and adjustment mechanisms for office chairs.

– In addition, on a Norwegian scale, we were a significant supplier of electrolytic surface treatment in the form of zinc plating and nickel plating, but now it has been a number of years since we shut down the electroplating department, says Aalrust.

– That department was simply not profitable anymore.

Follow-up tools and automation

Stantek AS has now survived for 75 years in a highly competitive industry, and as in the rest of society, development is going at an increasingly furious pace. So does the international competition.

– We have never been a billion-dollar company that can take on large investments straight away, as some of our foreign competitors can do. Our motto has always been that we earn the money before we spend it. But throughout our history, we have been good at finding smart and competent solutions that have made us competitive in the big world. Not least, we have been skilled at tracking tools and automation. We have always had a reputation for being fast, reliable and competitive. It has earned us many large and important contracts, says Aalrust.

Subcontractor of steel components

It is mainly as a subcontractor that Stantek AS has kept the business going through good times and bad. There are not a few Volvo, Renault and a number of other car brands that have been equipped with critical steel components from the Kongsvinger company over the years. The same applies to office chairs, windows and a number of other products from larger and smaller manufacturers at home and abroad.

– Over such a long time, there have naturally been both ups and downs with varying activity and profitability. But with good adaptability and sobriety, we have managed to keep the business going as an independent, family-owned business. We are proud of that, says Aalrust.

A time for everything

Today, Stantek AS is a pure subcontractor, and much of the production has been converted from punching items and in-house punching tools to thin sheet products in standard tools. The brothers Oddvar and Bjørn Aalrust are still the owners, but Oddvar retired as general manager nine years ago, and at the age of 70, Bjørn is now counting the months before he too joins the ranks of the pensioners. But a new generation of Aalrust is ready to take over as owners, and the brothers expect that Stantek will continue for many years to come.

– We have a skilled general manager in Hallvard Sletmoen, who, together with skilled and loyal employees, will continue to drive the business forward when we retire for good, says Bjørn Aalrust, who admits that it will be sad to leave the factory premises where he has spent his entire working life, but who looks forward to spending more time in the boat on the Oslofjord.

– There is a time for everything. The most important thing is that new forces keep the wheels turning.